We want to prevent mixing of foreign matter (contamination) by installing a centrifuge inside our clean room.

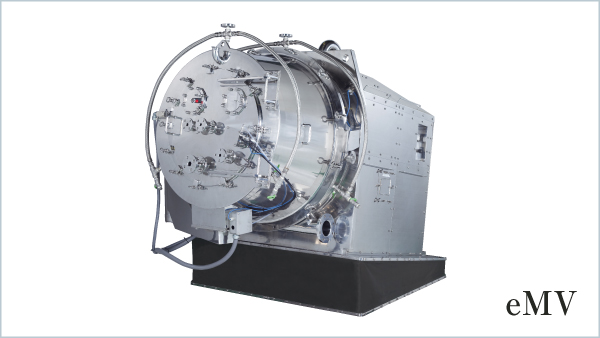

We received a request from a pharmaceuticals manufacturer, A Corporation, who were planning to construct a new factory, “By installing a centrifuge in the clean room we want to prevent mixing of foreign matter (contamination).” When we proposed the JMP-S horizontal centrifuge ,based on the their budget, they omitted the automatic functionality of the JMP-S and introduced the eMV.

As a result of using our centrifuge, work time was reduced, and work efficiency increased.

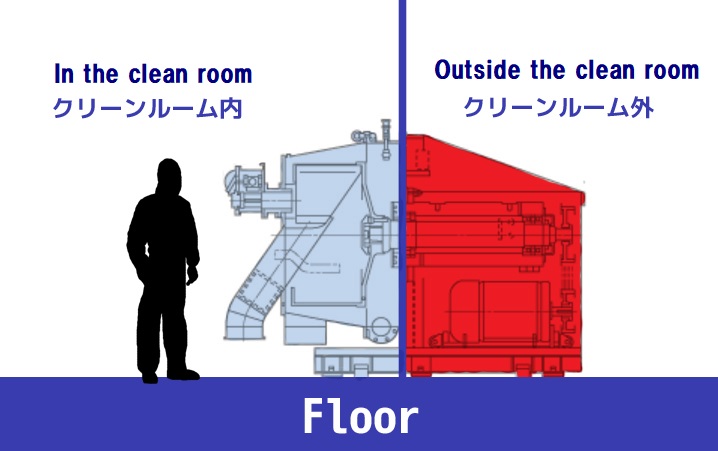

As we were able to divide this horizontal centrifuge with the clean room wall, into a pharmaceutical manufacturing processing unit and a motor drive unit, and also as the basket came right in front of the operator, it is possible to clean the interior surface and the back of the basket, and so on, without any blind spots and to check the cleaning.

In addition, since the eMV proposed here requires the operator to manually carry out the discharge performed automatically by the JMP, the cost of the machine can be kept down compared to the JMP.

Since the eMV basket is positioned diagonally, the workload of the operator when collecting crystals is lightened.

We were told that it is possible to perform the task of exchanging the filter easily compared with a vertical type, leading to reduced work time and increased work efficiency.

Key Points

Cleaning and checking cleaning are easy

If the casing is opened, since the basket is right in front of you, cleaning and checking the cleaning are easy.

In addition, due to the structure with no liquid pooling as there is no dead space in the processing area, internal inspection is easy.

Filter replacement task is easy

If the casing is opened, since the basket is right in front of you, the filter can also be easily replaced.

Installation area within the clean room is small

Since the drive unit and manufacturing unit are isolated with a wall, only the processing unit is installed inside the clean room, and the drive unit is placed outside the clean room, so the installation area within the clean room can be kept small.

Diagonally positioned basket makes burden on operator small

As the casing release section is diagonal, when taking out crystals, the burden on the operator can be lightened.

Machine cost reduction

By omitting the automated functionality, the machine cost can be kept down,

Company supplied

The pharmaceuticals manufacturer, A Corporation

Centrifuge supplied

For any questions or inquiries regarding centrifuges, feel free to contact Matsumoto Machine Sales, the sales arm of the pioneering centrifuge manufacturer.