We will meet your needs

With the technology, experience, and know-how accumulated over many years as a

centrifuge pioneer, we will ask customers about the factory layout, usage methods, and

products they wish to separate by filtration, and then propose and customize the optimal

centrifuge that is most effective and efficient for the customer.

In order to make your current equipment more comfortable and efficient to use, we can

improve your current machine and provide additional options. Please feel free to contact us

via the inquiry form.

Gains in effectiveness through customization

- Reduces the time required for product switching

- Since the basket can be raised up, the operator can reach between the basket and casing

to clean, as well as visually confirm that the cleaning was completed without any problem.

By shortening the cleaning and cleaning confirmation time in this way, the product switching

time can also be shortened.

- Enables free layout of equipment in the factory

- The equipment can be placed on a cart and moved. Depending on the product you wish to

manufacture, you can freely change the layout of the equipment in the factory.

- Increases the product recovery rate

- Crystals that have been separated by filtration in the centrifuge can be scraped off to the

very edge of the filter cloth, making it possible to increase the product recovery rate.

- Enables filtration tests for various liquids with a single R & D centrifuge

- By adding the filter ring of the LAC centrifuge used for R & D, such as a filter cloth ring, an

electronic beam ring, or a wire gauze ring, it is possible to test filter particles of various

sizes in a single device.

- Reduces noise and the load on the building

- Altering the shape of the feed pipe according to various conditions such as the liquid's flow

rate and viscosity or the state of the crystals, makes it possible to reduce the vibration and

noise of equipment, so reducing the load on buildings and noise problems.

- Shortens production lead time

- Changing the crystal washing pipe nozzle allows the cleaning solution to be spread over a

wide area of the crystals.

Shorter crystal cleaning time reduces the production lead time.

- Enables automatic cleaning of the equipment interior

- The CIP cleaning system enables automatic cleaning of the device interior with cleaning

agents without the need to disassemble the device.

Installing a nozzle suitable for the equipment shape and the user's product characteristics

ensures excellent cleanability and greatly reduces the workload of equipment cleaning.

- Enables filtration tests on samples of various amounts with a single R & D centrifuge

- By enabling replacement of a basket for 400 ml and a basket for 2000 ml, filtration tests of

various amounts of samples can be performed by 1 device.

*Normal models do not support the basket exchange mechanism of the LAC 400 and LAC

2000.

- Reduces the task of fracturing crystals

- A crystal scratching and crushing device can be attached that automatically scratches off

and crushes hard crystals following the separation by filtration.

This lightens the workload of operators who manually crush crystals to collect products.

- Prevents contamination with foreign matter

- The exterior of the equipment is made of stainless steel to reduce the risk of paint peeling

off due to aging and entering the product as foreign matter.

- Shortens cleaning time

- The processing of the panel to round the corners of the device makes it easier to wash

away crystals that tend to accumulate in corners with the cleaning solution, thus shortening

the cleaning time. It also reduces the risk of contamination when users switch to another

product.

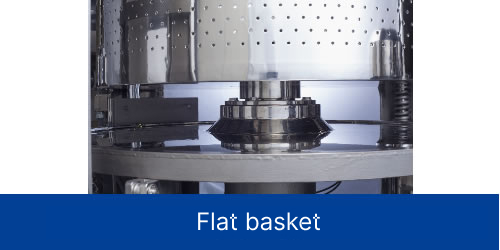

- Shortens cleaning time

- Making the basket bottom flat allows the operator to reach between the basket and casing

to clean, as well as visually confirm that the cleaning was completed without any problem.

By shortening the cleaning and cleaning confirmation time in this way, the product switching

time can also be shortened.

- Enables easy, reliable, and quick washing with two touches

- Simply by folding the filtrate scattering prevention plate outward, the reverse side of the

basket bottom can be reliably and easily cleaned with two touches.

Ideal for pharmaceuticals that require lot control and in multi-product manufacturing to

avoid hated cross-contamination.

- Prevents contamination with foreign matter

- Attaching a belt cover prevents the abrasion powder generated by the belt from mixing into

the product.

- Increases the product recovery rate

- By vigorously blowing air onto crystals that have been separated by filtration in the

centrifuge, residual crystals attached to the filter cloth can be removed, thereby increasing

the product recovery rate.

- Reduces running costs

- Using a metal filter material called an electronics beam screen eliminates the need to

replace the filter cloth and reduces running costs.

Also, since there is no need to replace the filter cloth, the operator's workload is reduced.

- Enables a clean working environment

- Using an electrically powered opening and closing device for the equipment avoids oil

leakage associated with hydraulic pressure, enabling a clean working environment.

- Enables temperature management of products

- A thermal insulation jacket enables the product to be kept warm or cold as is during

separation by filtration.

Please ask us anything concerning customization.

The above are some examples of customizable options.

After hearing about your current issues and how you want to employ the centrifuge, we will

make a comprehensive decision and suggest the optimal centrifuge options, usage

methods, driving programs, and so on.

Please feel free to contact us using the following details.