Cross-contamination refers to the case in which two products are being processed or manufactured, and one product is the source of contamination in the other product’s manufacturing process.

Specifically, it refers to the case when one machine is used to make two products, and the second product is manufactured while some of the first product still remains inside the machine. So, the first product is mixed into the second product, resulting in contamination.

It is important to prevent cross-contamination in the manufacturing process at all manufacturing facilities, including for pharmaceuticals, chemicals, foods, and electronics materials.

Preventing cross-contamination

(1) Use different centrifuges for different products being manufactured.

(2) When a wide variety of products are manufactured in one centrifuge, it is necessary to improve the cleanability so that there is no residual product.

The Matsumoto Machine Group offers options and specifications that emphasize cleanability.

For ease of cleaning …

(1) The casing opens up fully to 90 °

By opening and closing the casing, the basket will open, and the centrifuge casing interior, the entire basket, and any attachments can be washed down to the smallest parts. This enables a sufficiently clean centrifugal process.

In our centrifuges the casing opens firmly up to 90 ° upward, making it easy to clean and confirm cleaning when entering the machine to clean it.

Also, since it opens to 90 ° firmly, there is no possibility of the casing falling ensuring the safety of the operator.

(2) Basket Elevation Mechanism

By elevating the basket, it is easy to clean the casing interior and basket bottom, which contributes to reducing the workload on operators and improving quality.

(3) Casing Panel Finish

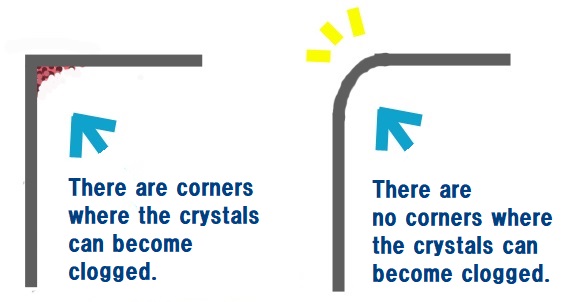

The casing has no corners and is rounded, so crystals do not get stuck in corners.

This prevents mixing of foreign matter or contamination when switching products.

(4) PATAN detachable splash prevention plate

The splash prevention plate, which can be easily attached and detached with 2 touches, enables easy washing of the bottom of basket in a short time.

(5) CIP cleaning nozzle and CIP cleaning system

With the CIP cleaning nozzle and CIP cleaning system, it is possible to automatically clean the metal parts inside the device with cleaning agents without disassembling the device.

Installing a nozzle suitable for the equipment shape and the user’s product characteristics ensures excellent cleanability and greatly reduces the workload of equipment cleaning.

(6) Immersion cleaning

The machine interior can be completely soaked and washed (immersion cleaning) by closing the filtrate outlet and pouring the cleaning solution inside the casing.

Therefore, there is no residue left after washing, leading to the prevention of foreign matter contamination (cross-contamination prevention).

By performing this immersion cleaning, it is possible to clean even fine particle residue.

In addition, Matsumoto Machine offers a number of unique cleaning options.

Please feel free to contact us to discuss details.