We want to introduce a GMP-compatible, fully automatic centrifuge – DMNβ

T Corporation, a pharmaceutical company that manufactures APIs and intermediates, consulted with us, telling us,“We want to introduce a fully automatic centrifuge that specializes in cleaning efficiency.” Centrifuge users who are mainly engaged in low-volume, multi-product production need to be able to switch products, ensure cleanability between batches, and check cleanliness easily.

So, this time, in addition to the casing opening and closing mechanism, we proposed, and the customer adopted, our optional CIP cleaning and basket lifting device.

(1) Casing opening and closing mechanism

(2) Internal CIP cleaning device

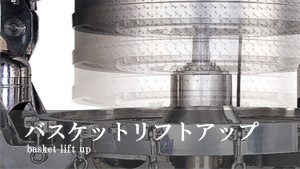

(3) Basket lifting mechanism

Performing CIP cleaning makes it possible to reduce the amount of cleaning work.

In addition, with some products, the operator risks exposure to highly pharmacologically active powders and liquids, but this risk of exposure when releasing the product can be reduced by performing CIP cleaning under airtight conditions.

The basket lifting mechanism is an option that improves the workability at each stage at the rear of the basket, which was difficult to swab and visually check in previous centrifuges. The mechanism allows easy swab cleaning and visual confirmation, reducing the burden on the operator during cleaning. As a mechanical interlock, it has a fall prevention mechanism, so there is no risk of injury from the basket falling during operation.

We have received positive evaluations from customers who have adopted the options above for reducing the work of operators in the cleaning process and for being able to make the risk management for exposure more specific. As a secondary effect, more items can be handled by a single centrifuge due to the increased cleaning efficiency, and we have heard that production efficiency has increased.

Key Point – Custom specification to increase cleanability and reduce cleaning time

Casing Opening and Closing Mechanism

By making the casing an opening and closing type, the basket can be opened , allowing the user to do detailed cleaning inside the centrifuge’s casing, of the entire basket, of attached devices, and more. Therefore, a sufficiently clean centrifugal process is possible.

Internal CIP Cleaning Mechanism

Cleaning fluid can be sprayed almost anywhere inside the machine.

The material of the spray ball can also be made to suit wetted materials.

Basket Lifting

By lifting the basket up, the inside of the casing and basket bottom can be easily cleaned, reducing the burden on the operator and improving quality.

Companies Supplied

T Corporation, a pharmaceutical company that manufactures APIs and intermediates