Filter replacement is unnecessary! – Protect the machine operator with the electronic beam screen –

A customer that manufactures herbicides and pesticides, S Corporation, consulted us, explaining, “As we handle toxic products, we have to wear protective equipment like toxic prevention masks and gloves when replacing the filter or cleaning the filter, but the risk to the on-site operator is high. Due to the product characteristics, the filter becomes clogged, and the filtration level drops, so we have to regularly replace the filter. So, we want to reduce the exposure of the operator to risk from toxic products.”

And so, we proposed, and the customer adopted an electron beam screen (metal filter) that renders filter replacement unnecessary.

As a result of using our machine with the electron beam screen specification, filter replacement was no longer necessary, reducing the toxic risk to the operator, and it also led to a reduction in time spent on filter replacement and filter cleaning, and associated labor costs, as well as removing the cloth filter running costs.

Key Points – Protects the health and safety of the operator

Electron beam screen specification

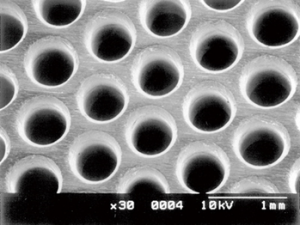

・The electron beam screen is a screen with a tapered hole (filtration surface of around 100μm) opened in a thin plate 0.5mm thick, and as the hole widens toward the discharge side, the shape makes clogging unlikely.

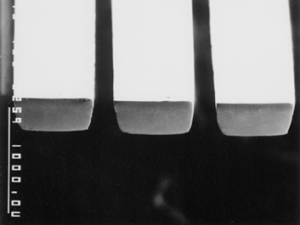

・ After turning processing, as the basket’s roundness is increased by applying a surface finish, and the runout is kept to a minimum, the residue cake layer after scraping the cake is reduced to a maximum of 5mm. (In the case of a cloth filter, it is at least 10mm.)

Filtration inhibition by residual cake is unlikely, and the next time’s filtration rate is increased.

・The residual cake layer is thinned, so the amount collected each time is increased.

・As cleaning can be carried out without removing the electron beam screen, screen replacement is unnecessary for a long period. This contributes to shortened work time and increased worker health and safety.

If required, it is possible to remove the electron beam screen when cleaning.

・Compared to when using a cloth filter, there is no risk of product contamination with fluff. Safe and high-quality separation is achieved.

・The electron beam screen is split mounted inside the basket, enabling maintenance costs when replacing to be kept to a minimum.

・The electron beam screen is completely sealed with the basket, so there is no risk of crystal leakage that occurs due to mistakes when installing a cloth filter.

(Basket with an electron beam screen specification)

(Electron beam screen hole expansion)

(Electron beam screen hole cross-section)

Company supplied

The manufacturer of herbicides and pesticides, S Corporation

Centrifuge supplied

For any questions or inquiries regarding centrifuges, feel free to contact Matsumoto Machine Sales, the sales arm of the pioneering centrifuge manufacturer.