・Since the crystal discharge outlet is large after the mass filtration process, there is no need to worry about deposition, accumulation, or clogging of the processed product.

・The large basket capacity, large filtration area, and large centrifugal force (800 ~ 900g) enable rapid processing of large quantities.

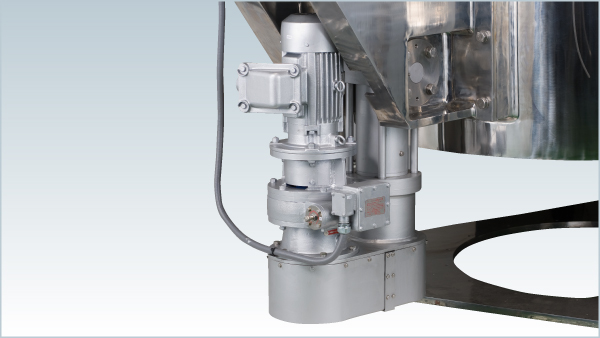

・With a simple structure that connects motor and basket directly, the device does not break down easily and is easy to maintain and handle.

・Considering the throughput, the installation area is small, so installation is possible in a small space.

・Since the motor is located in the center of the centrifuge, there is little vibration, so there is no effect on a centrifuge stand or buildings.

・Since there are no parts that wear, such as belts, there is no contamination and maintenance is straightforward.

・Various recipes can be programmed, and various safety devices are provided, so automated operation is possible.

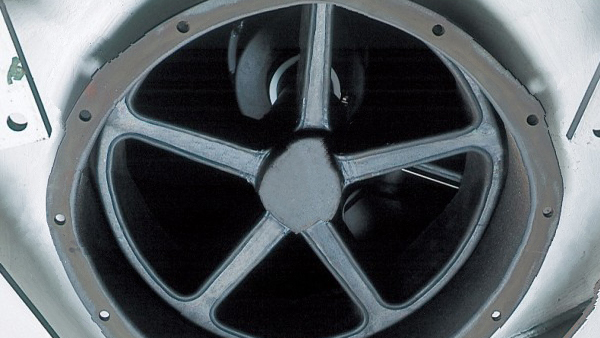

・Since the metal part and basket part are fully open, it is easy to clean and confirm the cleaning, reducing the risk of contamination.

・Regulation disks can be used for fully automated processing without human intervention, including slurry supply, separation, cake washing, crystal recovery, and cleaning, thus saving on labor without the need for operator intervention.

・Using a metal filter eliminates the need to replace a filter cloth.

・A nozzle is attached to the scraper device, and by injecting high-pressure air or nitrogen gas, the remaining crystals of the filter cloth can be detached and recovered with the highest efficiency. The device also facilitates the removal of liquid during reuse.

・When processing different chemicals, the filter cloth can be washed using high-pressure water, increasing efficiency.

・By adopting a multi-blade structure for the residual crystal scraper device (Matsumoto Machine patent), it is possible to recover crystals with the highest efficiency up to the limit of the filter cloth.

・The casing open and close device can be driven electrically. Unlike with hydraulics, the manufacturing can be conducted in a clean environment without fear of oil leakage.

・By performing Teflon processing on the stainless steel material, it is possible to process erosive chemicals and pharmaceuticals.

・All Matsumoto Machine centrifuges are custom-made. Regardless of the model, we respond to all requests, so please feel free to contact us if you have any requests or questions. After confirming the desired usage and conditions, our technicians will design from scratch and make a custom-made device.