We want ease of maintenance and daily operation.

The food product manufacturer, A Corporation, requested to us, “We want to upgrade to an inverter drive to be able to easily carry out all types of settings and maintenance, and daily operation. However, we want to operate according to the schedule used until now even with an inverter driven machine.”

And so, after hearings concerning the operation status of the customer’s machine and meetings, we proposed and supplied a specification equipped with a scraper device with a single motion.

As a result of using our centrifuge, all types of settings and maintenance and the daily operation were made easy despite hardly changing the operation status.

Key Points – Scraping process time reduced

Single motion scraper

By equipping the centrifuge with a single motion scraper, the scraping process time was reduced, and manufacturing was possible with the desired operation cycle.

We have the following two types of inverter driven scraper devices.

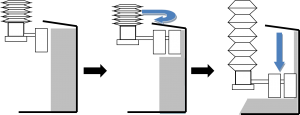

The two-motion type in which after a small blade cuts in it has a falling rotating action and a rising action.

◎ Two motion type image

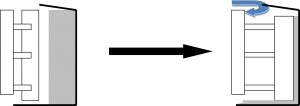

The single motion type in which a large blade cuts in and the cake is scraped off and drops and there is only a rotating motion.

◎ Single motion type action

In the case described here, the customer had the following two main requests.

① They wanted to upgrade to an inverter drive to be able to easily carry out all types of settings and maintenance, and daily operation.

② They wanted to continue with the same schedule used until now even with an inverter driven machine.

The advantage of the inverter driven type is that, compared to an oil pressure driven type, all types of settings and maintenance and the daily operability are easy to handle, so this meets the customer’s request ①.

However, the disadvantage of the inverter driven type is, compared to the oil pressure driven type, it takes time to start and brake, so one batch takes about 5 minutes longer than with the operation up until now.

The time taken for one batch was short as the product had good filtration characteristics, so if an additional 5 minutes were taken per batch, then we estimated the operating time would be extended by around 1 – 2 hours per day.

In order to eliminate this problem, we proposed changing the scraper device from the two-motion type already installed to a single motion type.

As a result, it was possible to upgrade to an inverter driven type in line with the customer request despite hardly changing the operation status.

Company supplied

The food product manufacturer, A Corporation

Centrifuge supplied

For any questions or inquiries regarding centrifuges, feel free to contact Matsumoto Machine Sales, the sales arm of the pioneering centrifuge manufacturer.