・A large amount of cutting oil can be recovered in a short time. Because it is a continuous centrifuge, the throughput is high, and a large amount of cutting oil can be recovered in a short time.

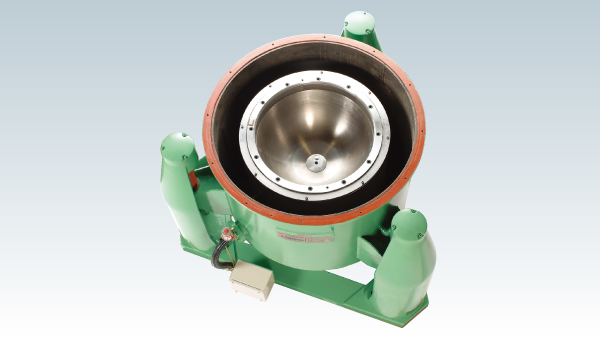

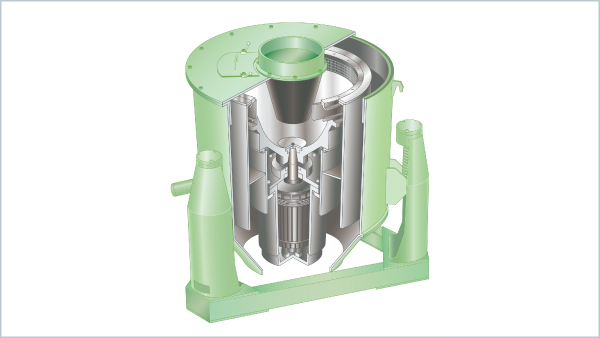

・Maintenance and inspection are straightforward. A simple structure and directly connected motor make maintenance and inspection straightforward.

・Whatever the variety of cutting chip, leave it to this device. The filtration screen can be changed according to the shape and size of the cutting chips. We also suggest a crusher or similar equipment to match the cutting chips.

・The vibration is low, so the building load on the factory is low. A three point suspension system is used for anti-vibration. Vibration is sufficiently absorbed, so the device runs smoothly. It also reduces the burden on factory buildings.

・The running cost can be reduced. Because the rotation of the basket is directly connected by a special electric motor, there are no expendable parts such as V-belts, brakes or friction clutches, so running costs can be reduced after introduction of the device.