・A variety of recipes can be programmed and regulation disks can be used for fully automated processing without human intervention, including slurry supply, separation, cake washing, crystal recovery, and cleaning, enabling labor-saving without the need for operator intervention.

・A vibration detector is installed as standard and the operation status is constantly monitored. As the machine is equipped with various safety devices, automated operation is possible.

・By inverting the filter cloth, all crystals can be recovered.

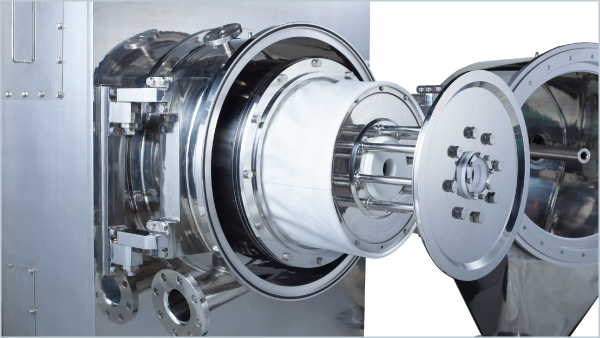

・The device is ideal for preventing contamination. The separation and purification part of the centrifuge and the drive unit are separated by a partition wall to prevent abrasion powder in the drive unit from mixing into the product.

・As the casing is fully open and the basket is in front of the operator, it is easy to clean and check the inside of the basket as well as the back of the basket.

・Since the entire process can be handled fully automatically, contamination due to operator intervention does not occur.

・CIP cleaning and immersion cleaning can be performed. The washing liquid is stored in the tank, and the basket can be soaked and washed while being rotated. Not even a few crystals remain.

・Because of the automatic operation, there are few opportunities for the operator to intervene, thus avoiding health hazards to the operator.

・All Matsumoto Machine centrifuges are custom-made. Regardless of the model, we respond to all requests, so please feel free to contact us if you have any requests or questions.

・After confirming the desired usage and conditions, our technicians will design from scratch and make a custom-made device.