OUR SERVICE

Matsumoto Machine will always provide all support to ensure our customers are successful. Since the founding of the company, we have been a successful partner in our customers' manufacturing processes. It is our pleasure that our customers can manufacture products safely, produce the best results in terms of production volume and efficiency, and that our customers can always make a profit. To this end, we believe that it is important not only to provide machines but also to provide the best service in the industry to keep our customers satisfied.

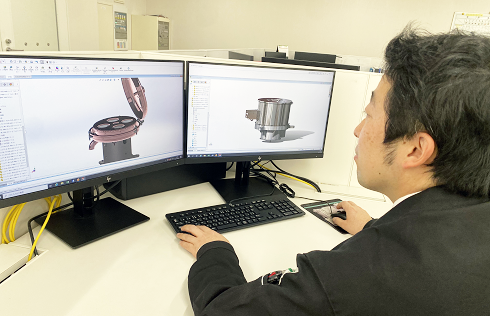

- Test Center & Consulting Service

- After listening to your problems and concerns, a technical-minded advisor will use his years of experience and expertise to recommend the optimal model of centrifuge with options, and explain how to use the centrifuge. As our products are used in a variety of industries, including pharmaceutical manufacturing, food manufacturing, chemical manufacturing and metal swarf processing, our company’s advisors have a lot of expertise in each of these industries, We are also developing new centrifuges every day so that customers can make new products. As a partner to increase our customers' competitiveness, we will help solve their problems.

- Installation & Commissioning

- Our company engineers can assist you with centrifuge commissioning. We will adjust the machine so that you can use it comfortably, and if you require, we will be present until the actual product is put into operation and will train you to use the machine.

- Training

- To produce high-quality products, it is important that the machines are operated by well-trained operators. We give our customers a special seminar so that our knowledge is correctly communicated to them. We can provide you with a work manual and an improvement and maintenance training program.

- Process Engineering Optimization & Product Tests

- For post-delivery improvements such as increasing crystal recovery as crystal discharge is poor due to high machine vibration, mechanics and technical teams will find solutions to customer challenges from a mechanical, electrical, or regulation perspective and offer optimal advice. Over 1300 customers have used our machines for more than 30 years after delivery. We will generously provide the knowledge we have accumulated over 80 years since our establishment so that you can use our product comfortably for as long as possible.

- Upgrades & Retrofits

- If the product does not produce the desired effect when used after delivery, or even if the product to be filtered has changed and cannot be processed properly, we will hold a meeting to determine the current situation and provide support by upgrading the machine even after delivery while also conducting tests together, so that the customer can use it safely and comfortably. This allows customers to use centrifuges that meet the changing needs of the world, for example, automation that improves production efficiency and washability, without the need to buy a new centrifuge. This increases production capacity and reduces running costs.

- Technical Support 24/7, Remote Support, Telephone Support & On-Site Support

- For problems such as sudden machine malfunction, our technical team finds solutions to customer problems from the perspectives of machinery, electricity, and regulation, and provides optimal advice. Also, we can confirm the problem locally as soon as possible depending on your request. If there is a local agent, the agent will provide support. This enables the plant to resume operating as quickly as possible. *There are agencies in EU countries.

- Maintenance Create and purchase a list of required parts based on a detailed maintenance schedule.

- Regular professional maintenance by our mechanics reduces the chance of sudden mechanical problems. This prevents unplanned downtime. Avoid unplanned downtime and associated costs by replacing critical parts and worn-out parts as part of preventive maintenance.

- Repairs & Spare Parts

- Arrange for spare parts for damaged parts to keep your facility running and minimize unplanned downtime. For basic parts we make spares ourselves. Therefore, it is possible to make parts quickly and arrange for them promptly.